Machining is a variety of processes used on a piece of material to cut that material into the needed final size and shape. This is done by a process of material removal that is controlled– and this is what EDM is used for. EDM or machining done with an electrical discharge is known also as:

- Spark machining

- Die sinking

- Spark eroding

- Wire erosion

- Wire burning

This is a process of manufacturing where a required shape is accomplished using electrical discharges or sparks.

Two types

There are two major types of EDM:

- Conventional

- Wire

EDM is used if conventional machining cannot do the task. It is a process that is used when a workpiece is difficult, electrically conductive and has precise geometric tasks or difficult requirements for surface finish. This is all involved in machining. For further information, you can find more at https://www.innomolding.com/wire-cutting/

Conventional EMD

This is described above and uses a tool to break-up the electrical current. The tool or electrodes are most of the time made of:

- Graphite

- Copper

- Copper tungsten

These electrodes are used to vaporize or melt the material leaving very little debris and making sure there is an accurate finished feature. This conventional method is important for tight tolerance forms and tooling that is complex with ultra-finishes.

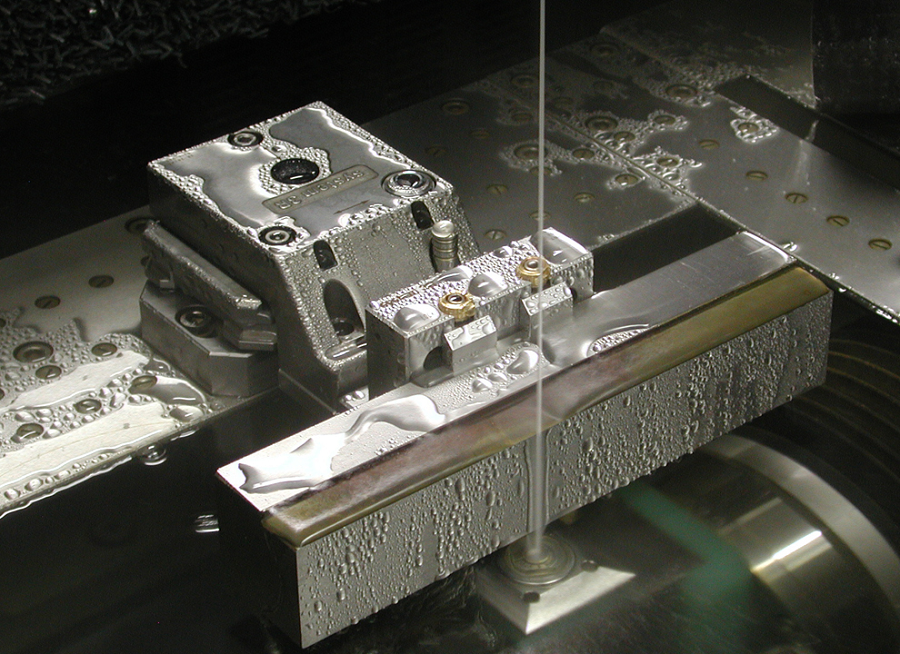

Wire EMD

Wire EMD uses a wire that is used to discharge the electrical current that is sent into the electrically conductive metal piece being worked on. Both the wire piece and the wire are set below a layer of “dielectric fluid”. This wire is taut and thin. It acts in this process as a “cathode”, usually able to cut entirely through the material. The operator or worker can change this in order so that it cuts only partially through, but complete cuts are common. This result is quite accurate and precise cut.

Further explanation

This is only a brief explanation of EMD and what it means in machining. If you are not sure what “machining” is, then do a Google search to find out more clarifying information. If you are not familiar with machining or the terms used – it is even harder to understand.